Anybody who has followed the world of superyachts on a regular basis has heard about a shipyard turning a hull. Some yards start construction with the hull upside down to make welding and other tasks easier. A yard then slides the hull out of the construction shed, uses cranes to flip the hull over, and returns the hull to its spot inside so construction can continue.

Many shipyards nowadays make this process look easy, but it’s not—especially when you’re talking about the hull of a supersize sailing yacht. That was the case when Royal Huisman in the Netherlands turned the hull on the 280-foot build known as Project 410.

When it launches, this yacht is expected to be the world’s largest with a single mast. That’s one heck of a big hull to turn, and the builder reportedly got it done in one try.

“In a seamless maneuver, four cranes lifted and turned this masterpiece midair over the adjacent canal,” the shipyard reported after the turning was complete. “The upright hull will be placed on a cradle and moved back into Hall 2, her home until completion.” With this significant step completed, the team will now proceed with developing onboard systems, outfitting and more.

Perhaps even more mind-bending is that as large as this hull section is, it’s still missing the bow, which is also under construction and will be attached during the next phase. Sister company Rondal is simultaneously building the carbon boom, mast and integrated sailing system.

It’s all in a day’s work, says Jan Timmerman, Royal Huisman’s CEO: “Four of the world’s 10 largest sailing yachts are either built by or under construction at Royal Huisman: Athena, Sea Eagle, Project 410 ‘85m New World Sloop’ and a second supersize sailing yacht.” Each one, he adds, exemplifies the advantages of large sailing yachts over motoryachts, which he says lack the thrill of hoisting sails while cutting through waves.

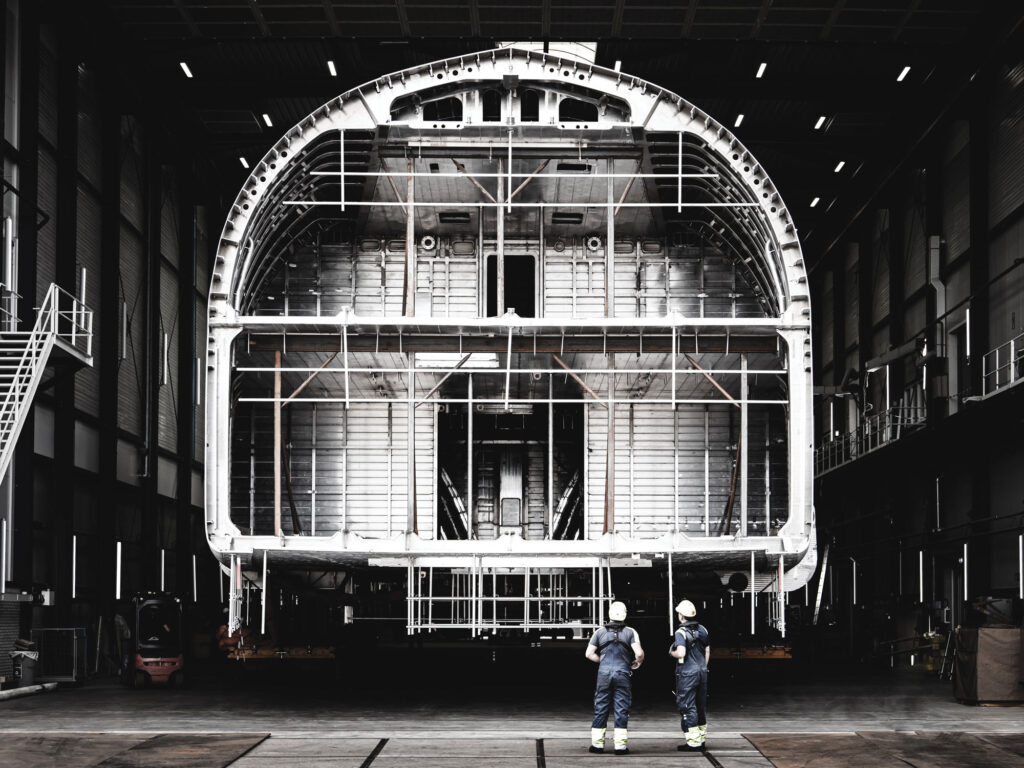

Yes, That Photo Is to Scale

Project 410 is a 280-foot yacht that dwarfs all the people and some machinery at the Royal Huisman shipyard. In order to build the aluminum hull at the facility in Vollenhove, the Netherlands, the construction hall shown at right had to be extended. Frers Design is responsible for naval architecture on the ambitious project.

It Takes Two

Whereas most yachts have one belowdecks accommodations level, Project 410 is being built with two. The project has been highly secretive, with Wetzels Brown tapped to work on the interior design. The yacht is engineered by Royal Huisman’s in-house team. The fact that this project even exists came to light at the 2022 St. Barths Bucket Regatta, and the Royal Huisman shipyard has been mum on most details ever since. That’s one reason why the turning of the hull was so notable; in order to achieve the turn, the hull had to be brought out into daylight, where images could be captured. Four cranes lifted and turned the hull over an adjacent canal, revealing the fact that there are two accommodations levels inside the part of the yacht that will be mostly below the waterline. After the turning was complete, the hull was placed on a cradle and moved back into the construction hall. That’s where it is expected to stay, shrouded in mystery, until launch.