My mind numbed as I stared at the yellowed document. The clutter of data was the EKG of a long-forgotten build. The pulmonary numbers on the sea-trial report revealed no shortage of air and fuel, but the patient wasn’t up to speed. The diagnosis had been easy: a No. 2 pencil deficiency resulting in bloating. It was time for Weight Watchers.

Real boat design is a whole lot of work, not a fun factory for imagineers. Back in the day, getting a design right meant noodling longhand with weight and center of gravity. Damn you, Archimedes.

I’d actually been noodling in my mind since I was a young tot. I had been fascinated with the underbellies of boats. They had been something of a mystery in the soupy waters of New York’s Long Island Sound, but all was revealed following our family cruiser’s chance encounter with a piece of the sound’s underskirt. I had stared in wonder as the damaged vessel emerged from the murk on a railway at a shipyard on City Island in the Bronx. I was so moved, I began recreating the mishap with toy boats, and in retrospect, I am sure the incident was responsible for my field of study.

A primer on the use of a planimeter to measure irregular shapes, and an appreciation of Archimedes’ views on displacement, came early in the curriculum. They were my first hints at the tedium required to draw a load waterline close to where it might end up. I dug into the challenge, sculpting a shapely planing hull and determining its displacement and center of gravity with my planimeter and Simpson’s rule. I recall a fellow student skipping the complicated math and birthing a simple barge. I wouldn’t be at all surprised if he made a go of it in the field as an imagineer.

Read More from Jay Coyle: Tell Tales

There are two ways to conjure a boat’s weight and center of gravity: endless hours of tallying its DNA or what I refer to as the amusement-park method, which is just taking a guess. While the computer has made both methods easier, the irony is that neither ensures success. Boatbuilding is an imperfect science, and few builders confirm the numbers along the way by checking the weights of all that’s laminated, welded, glued, screwed and carried aboard. They often rely on a midnight bath pre-launch before investing in paint for a boot stripe.

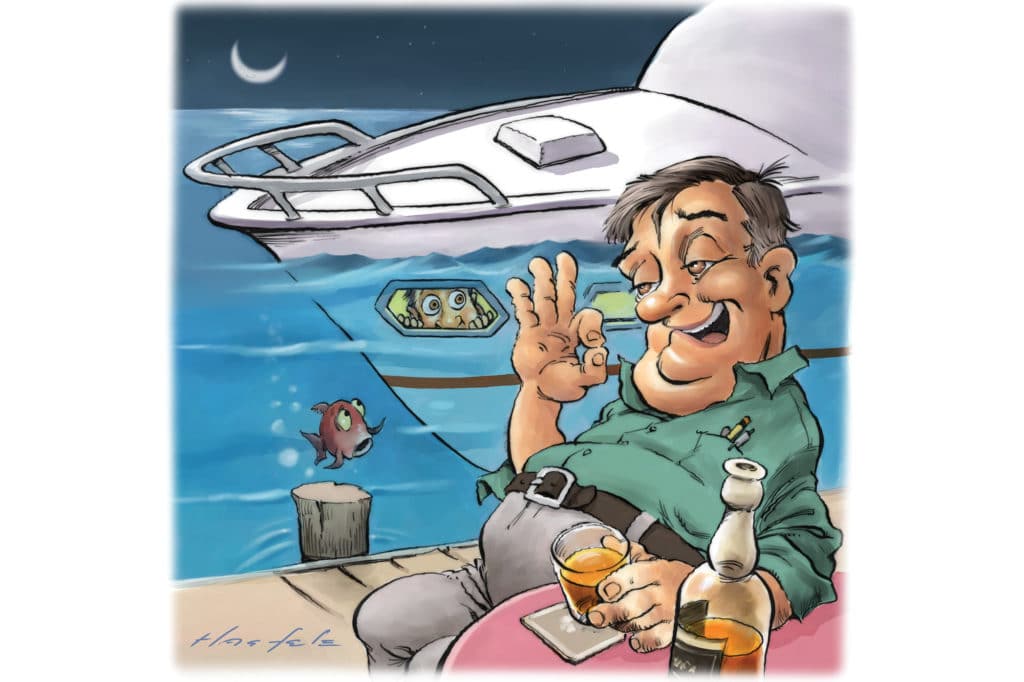

An old boatbuilder once told me that the method of waiting to weigh made sense, as most designers were drunks. He had adopted the practice from a well-known boat designer who’d completed his weight calculations at pre-launch, directing the placement of lead ballast while sitting across the canal beam-to, nursing a bottle of scotch.

My patient’s prognosis had been excellent. Her hull form had been noodled by a capable designer, not by a drunk or a carny. Her modest weight gain had been treated with post-launch bariatric-belt tightening, and her owner had been wise and not stuffed her like a Thanksgiving turkey.

The bottom line on performance: Watch the weight.