This content is also featured on our Princess Passport. To return or learn more, visit: The Princess Passport

Prior to departing from the dock in Plymouth, England, the captain of our Princess Yachts R35 called out: “If at any time you feel sick during the ride, let me know.”

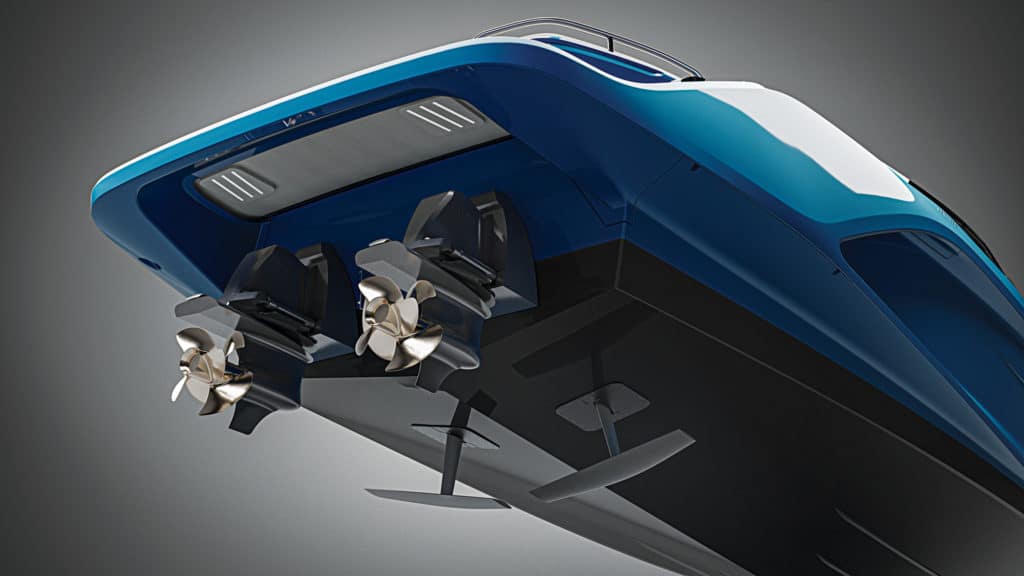

Forty-five knots later, our R35 and five-person crew were streaking across a rain-spattered Plymouth Sound. The boat’s twin 430 hp Volvo Penta gasoline sterndrives sang with all the power of a tenor and all the range of a soprano. (The builder says speeds up to 50 knots are possible.) Our captain put the wheel hard over, and the hull gripped the ocean with purpose. The boat stayed level in the turn. No lean. No heel.

I felt like an astronaut taking a G-force-tolerance test, laughing the whole time. In fact, everyone on board was laughing so hard, it sounded like a boat full of kids, in spite of the abundance of gray hair. Our helmsman kept the wheel pinned over, and just when we thought the boat couldn’t turn a tighter circle than one boat length, it cut that down by several feet. We made a third pass, turning even tighter. The boat seemed to be doing a pirouette on the props. When the wheel came straight, the R35 was back up to that mid-40-knot speed almost instantly. The experience seemed more like flying through the air than riding on the water.

This boat’s performance comes, in part, from under the water in the form of foils. Not the foils most people think of, where the boat is raised above the sea, sitting on blades that look like skis. Instead, the R35 has what’s called the Princess Active Foil System. Picture two T-shaped wings tucked into the hull, forward of the sterndrives. When the foils are deployed, they don’t lift the boat up, but instead constantly adjust the R35 for heel and running attitude, ensuring stability. Princess says the foils also reduce hydrodynamic drag by up to 30 percent, increasing overall performance and that slick feeling underway.

The foils operate independently. Princess developed them in cooperation with BAR Technologies, the group behind Britain’s last America’s Cup vessel. Additionally, computer software running the foils calculates their position around 100 times per second. That’s a lot of math happening at warp speed. Based on my time on board the R35, it all works.

Our R35 was operating in what Princess calls comfort mode. For owners looking for an even more thrilling ride, there’s a second mode dubbed “sport.” Sport mode essentially allows the R35 to lean into those turns. We didn’t run the boat in sport mode, but given my comfort-mode experience, I imagine it would feel something akin to shooting down a mountain in a super-G, heeled over and attacking slalom gates like Lindsey Vonn.

While the foils enhance performance under the water, the R35’s aerodynamic exterior design assists above it. Princess used 3D modeling and computational fluid dynamics to create the R35’s shape, one that, in profile, resembles a knife blade. The sheer line transitions from a fine point at the bow, creating a seemingly straight line down the side that resolves at sweeping wing stations aft. It’s a clever bit of blending of linear and curved lines, creating an aggressive lean-forward look with all the sleekness of a sports car. It makes sense when you consider that auto-design firm Pininfarina (think Ferrari) helped create the R35’s exterior look.

Form follows function as the design allows air to flow over, around and through the vessel unimpeded. Less air drag—like less hydrodynamic drag—means better performance. A raked windscreen directs air over the helmsman and guests, keeping everyone’s hair (mostly) on their heads and reducing noise in the cockpit at speed.

The last bit of the R35’s performance puzzle is its build. It’s made entirely of carbon fiber via resin-film infusion. Resin-film infusion is different from traditional resin infusion used in fiberglass builds. With typical resin infusion, the builder says, the resin flows through the fiberglass cloth. In resin-film infusion, the resin is “already contained within the fabric as layer.” The builder says the carbon fiber is hand-laid up in layers, via dedicated craftsmen, and it is vacuum-bagged and baked in an oven at 80 degrees Fahrenheit for around 12 hours. The essential benefit is that, while resin infusion helps reduce weight by about 15 to 20 percent compared with traditional fiberglass layups, resin-film infusion reduces weight by up to 25 percent. And every pounds counts.

Resin-film infusion also means there is no gelcoat. The benefit, according to Princess, is additional weight savings of about 660 pounds and the elimination of potential print-though issues when the boat is painted.

While mostly known for its yachts and express cruisers, Princess Yachts has shown with the R35 that it has the skills and wherewithal to produce a high-performing sports boat that pushes the boundaries of technology across the board, from the stabilizing foil system to the carbon-fiber build. Will the lessons learned from the R35 see use in the builder’s larger models in the future? It’s possible. But for now, if you get the chance to run the Princess Yachts R35, just go. The fun this boat offers is infectious, and it will leave you laughing long after you go home.

Take the next step: princessyachtsamerica.com

This story originally published in the February 2020 issue of Yachting Magazine