The editors at Yachting have teamed up with the experts at Imtra to bring you advice on how to keep your boat in Bristol condition and get the most from your hours spent out on the water. For more great tips, see Next Level Yachting with Imtra »

What is the difference between horizontal & vertical windlasses?

The terms “horizontal” and “vertical” refer to the orientation of the main-shaft of the windlass, so if the shaft is parallel to the deck, it’s a horizontal windlass, and if it is perpendicular to the deck, it is a vertical windlass. One way to think about this is the way that the chainwheel spins when the windlass is being operated. If the chainwheel spins like a merry-go-round, it’s a vertical windlass, and if it spins like a Ferris wheel it’s a horizontal windlass.

Can windlasses handle rope & chain?

All anchor windlasses are designed to handle chain, but not all windlasses can manage rope. To manage rope a windlass must have a chainwheel that has grooves or teeth on the inner part of the wheel to grip the rope. The majority of windlasses that manage rope are equipped with what is called a pressure finger; a spring-loaded metal or plastic arm that pivots on a post, using the spring pressure to push the rope into the inner grooves of the chainwheel. Generally speaking, vertical windlasses are better at handling rope than horizontal windlasses because the rope makes a 180-degree turn around the chainwheel on a vertical windlass, meaning the chainwheel has more contact with the rope, giving it a better grip than a horizontal windlass which only makes contact with the rope for roughly a 90-degree turn.

How do I determine the size and power of windlass for my boat?

While many boaters often try to size the windlass based on the size of the boat, the main determining factor to consider is the combined weight of the anchor, chain and/or rope that the windlass will be deploying and hauling. Your windlass is intended to lift the anchor and rode and should not be used to pull the boat up to the anchor. A typical rule of thumb is to total the weight of your anchor plus rode and multiply that weight by three. Whatever that number comes out to should be the minimum “power rating” or “maximum load” of the windlass. For example: if your ground tackle weighs 300 lbs. you should have a windlass that is rated for 900 lbs. or more. So if you use all chain and no rope in your anchor rode, you will need a more powerful windlass than if you use a combination of chain and rope, as chain is heavier than rope.

Can a windlass bear the weight of my boat?

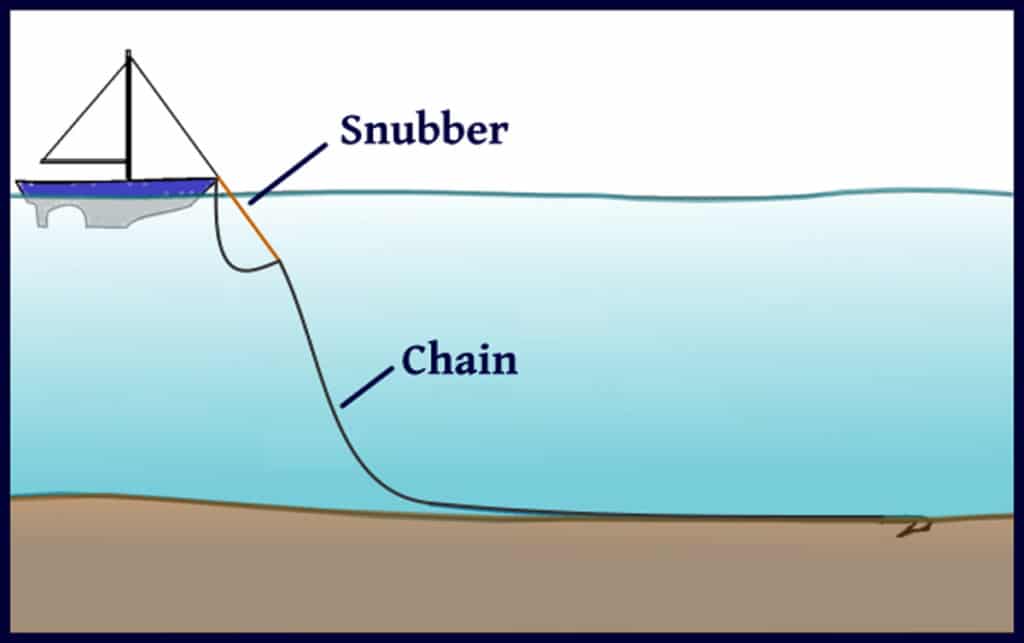

The short answer is no. Much like you shouldn’t use the windlass to pull the boat up to the anchor, you also shouldn’t leave the weight of the boat resting on the windlass when anchored. Leaving the weight of the boat on the windlass can shock-load it in waves or gusts of wind which will cause damage to the chainwheel, gears and mainshaft of the windlass.

If you are using rope, you should wrap that rope on a cleat at the bow, taking the tension off the windlass. If the rode is all chain, you should use a snubber line which has a hook on one end to hook into a chain link, then cleat the other end to the boat, and let more chain out of the windlass until the snubber line is taught and bearing the weight of the boat, not the chain on the windlass.

Do I need a circuit breaker for my electric windlass?

Every electric windlass should have a circuit breaker to protect both the electric motor of the windlass from burning out under extreme load, as well as to prevent damage to the deck or hull of the boat. Many windlasses are strong to enough to rip themselves right off the deck of the boat, or bend and break a bow roller if the anchor were to get permanently stuck on something, so it’s important to have a circuit breaker to kill power to the windlass if it is exceeding its maximum load.

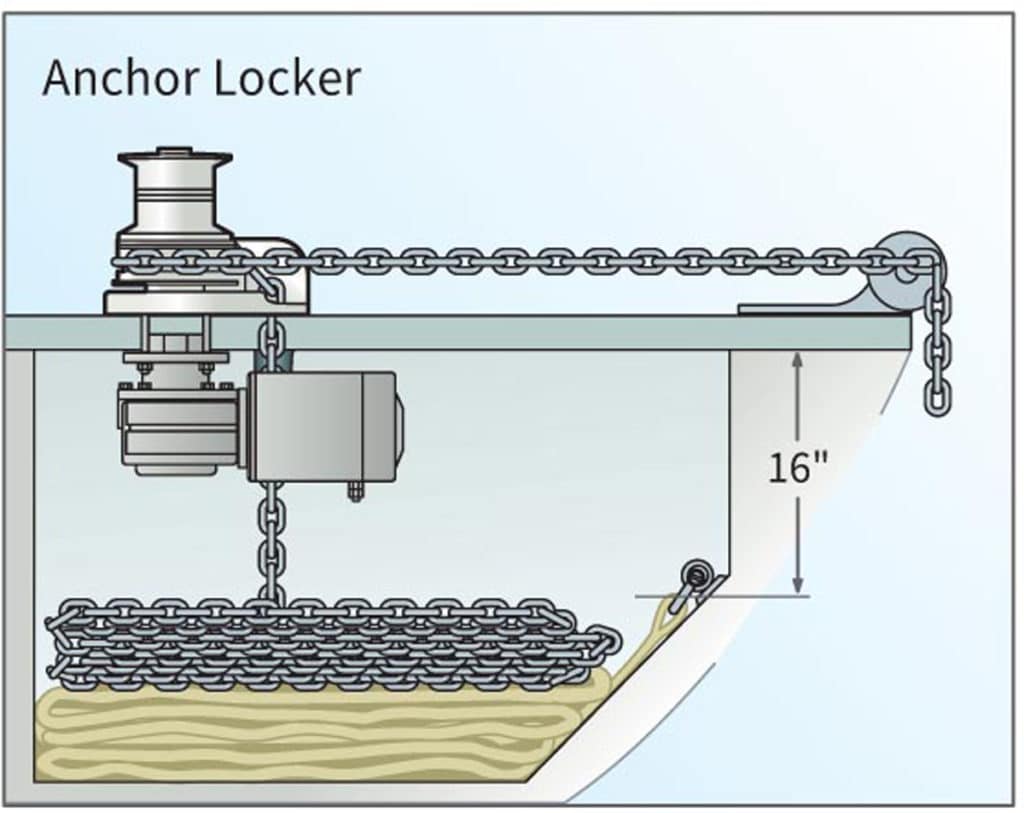

How big of an anchor locker do I need for an electric windlass?

As a general rule an anchor locker should have at least 16 inches of clearance from the underside of the deck to the top of the pile of your anchor rode. Anything less can cause the windlass to jam or tangle the rode up. For a vertical windlass with the motor and gearbox below deck, a deeper anchor locker is required than for a horizontal windlass where the entire windlass is on deck.

What control options do I have to operate my electric windlass?

If you use a solenoid control box in the circuit, which the vast majority of windlass installations do, then the control options are nearly endless. With a control box, you can wire just about any up/down control switch you prefer to operate it. You could use a footswitch up at the windlass, an up/down switch mounted at the helm, a plug-in handheld remote, a wireless remote or even a combination of all of the above. However, without a control box, you’d need to use a high-amperage switch that can handle the full electrical load of the windlass, which would typically be a large footswitch installed in the deck near the windlass.

If you haven’t yet chosen your windlass, or just want to learn more, be sure to check out our article on How to Choose the Right Anchor Windlass or feel free to reach out to our team of experts with any further questions.