Hauling an anchor has been enjoyed by no one, anywhere, ever. It’s a back-breaking chore that can only be resolved with one thing: an anchor windlass. But, blessing though they may be, anchor windlasses are known for having numerous issues that can stop them cold. The good news is that it’s usually easy to troubleshoot and resolve the problem in short order. Here’s how to figure out what the windlass issue is, and hopefully, get it running again.

Slip Sliding Away

When the windlass appears to be operating properly, but the rode isn’t moving, the most likely issue is a simple clutch adjustment. Check your owner’s manual for how to adjust the clutch (some windlasses have a knob you can turn by hand and others require a winch handle), tighten it up, and give it another try. If the clutch is sufficiently tight, but the windlass still isn’t taking up line, there’s a possibility that the gears are stripped, and the problem will have to be addressed back at the marina.

No Signs of Life

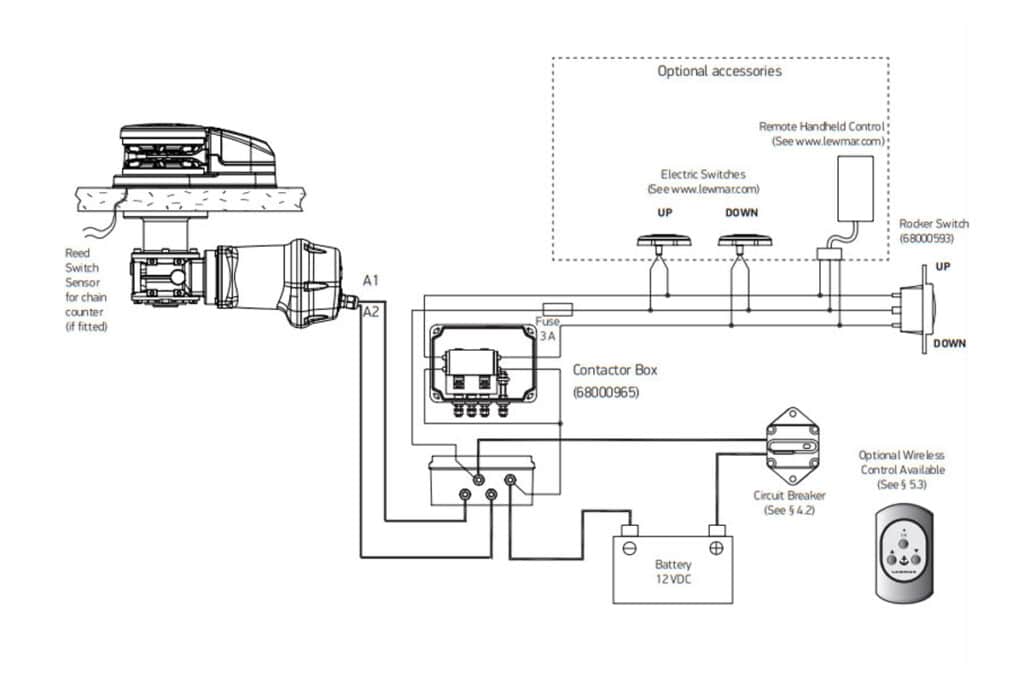

If you flip the switch and nothing happens at all, it’s likely an electrical issue. Step number one is to check the circuit breaker. If the breaker is popped ,reset the breaker and try again. If not, you need to ascertain why and where there is a lack of power. Use a voltmeter to check both sides of the breaker and switch to make sure they’re working properly, then check the motor itself. If there’s no power, check the cables running to the motor. If it shows power, but voltage drops way off when you hit the switch, you have a battery problem and the motor isn’t getting sufficient juice. If there’s plenty of power, the next suspect is the solenoid switch. A clicking noise is a sign that the contacts are corroded or it’s given up the ghost and needs to be replaced. The solenoid is good, but still no luck? In that case, the problem may be more significant, likely in the motor itself, and you’ll need to get that anchor up manually and call in a pro who can disassemble it and diagnose the motor problem.

Deployment Denied

When you’re trying to let out the rode and the windlass keeps clunking, but nothing else seems to be happening, there’s a good chance you have a tangle below decks. You’ll have to access the rope locker from below and straighten out the rode. If you don’t see an obvious tangle, also look for snags, as the rode can become snarled around a bolt-end or a hatch frame in the anchor locker.

Starts and Fits

Does your windlass work fine for a bit, shut off, then work again a few minutes later? If so, chances are the problem is with the operator, not the windlass. This is a sign of overloading the unit and an automatic shut-down taking place to prevent overheating and further damage. Most of the time this is caused by people using the windlass to pull the boat forward to the anchor. Remember, these units are designed to lift the anchor up, not pull your boat along and wrench the anchor out of the bottom. Next time, use the boat’s engines to pull forward while the windlass takes up slack. When the rode is vertical, cleat the line then shift the boat’s engines in reverse to pull the anchor free. Then and only then, resume operating the windlass to haul up the anchor.

What Goes Up Must Go Down

Except for when it doesn’t. When a windlass operates in one direction only, it’s usually another solenoid issue and this time the switch is stuck. It may start working again if you rap the exterior of the switch, as sometimes that will jiggle it free. This is a temporary fix at best, however, and you should replace the switch before your next cruise.

Naturally, there are other problems that can arise with a windless. Stripped gears, broken teeth and worn brushes are all issues that you might encounter. Troubleshooting and fixing these problems, however, generally require the services of a boatyard and/or replacing the unit. Which, of course, you’ll want to have happen asap—unless you’re the one person who finds hauling the anchor manually fun exercise.