Technology is entering into every part of boats now, from carefully formulated resins and vacuum-bagged hull construction to integrated monitoring and remote notifications of onboard alarms. But original and aftermarket equipment providers are constantly looking to improve their products and engineer in better performance, quieter operation, and smarter use of resources. The best news: those suppliers are succeeding now, so there’s no need to wait. Here are six ways to rethink an upgrade or refit on your boat.

Charging Ahead

There are those who say Mr. Murphy must have been on a boat for a long weekend before he returned to his legislative office and drafted his namesake law. And if that is true, one can bet that his voyage involved a marine battery in one way or another. If you’ve had similar experiences, you may be both surprised and relieved to learn that there are companies working on this problem.

One such company is Valence Technology, which works in battery chemistries that fall under the Lithium-ion umbrella. But there the similarities with your laptop battery end. Those laptop and cell phone batteries are generally Lithium cobalt oxide, and we’ve all heard about laptop batteries catching fire— obviously that technology would not be welcome aboard in a large marine application.

“Lithium phosphate as a chemistry is very different: It is intrinsically safe, and it’s almost impossible to cause it to have a thermal event,” says Robert Kanode, president of Valence Technology. “So it really is night and day between the different Lithium-ion chemistries.”

This type of battery would seem to have a lot to offer beyond basic safety. “Compared to lead-acid, we don’t out-gas, there’s no maintenance,” says Kanode. “If you store a boat in New England during the winter, you have to take the lead-acid batteries out and trickle charge them. With Valence batteries, you just leave them in the boat all winter without any charging or concern of damage.” According to Kanode, the batteries are also lighter, smaller, and offer higher capacity than a lead-acid battery for a similar application.

We’ve come to realize that nothing on a boat is truly “no maintenance,” but those from Valence seem to tend to themselves. “Our batteries have about 60 logic points that they report out three times a second,” says Kanode. “So you can have real-time reporting on battery performance, temperature, and state of charge. For any potential problems that you may be concerned about, like low voltage, the battery system will automatically give you an alarm, should a problem occur.” The system is designed to make unanticipated, catastrophic failures a thing of the past.

Refit Considerations: Explore newer battery technology, add monitoring, and reduce maintenance.

Valence Technology, (888) 825-3623; www.valence.com

Keep It Fresh

Watermakers continue to get smaller and quieter and require less maintenance—just set it and forget it, except when they go one better than that. Sea Recovery has introduced two models that will network into a boat’s NMEA 2000 monitoring system.

“More owners want to integrate more systems on the boat,” says Chris Rollins, vice president of sales for Sea Recovery. “Our NMEA 2000-compliant systems allow for this integration, letting the user operate and monitor all functions from anywhere there’s a NMEA 2000 interface.” The company’s Aqua Whisper DX and Aqua Matic watermaker systems are NMEA 2000 enabled.

That means fewer trips to the engineroom. The operator will get the same level of system monitoring, if not better, since NMEA 2000 can be programmed with specific parameters regarding tank levels and cycling that allow the user to know when something is happening other than what was planned on a voyage.

Also, the watermaker can figure into the overall efficiency of the vessel. Freshwater supplies can be allowed to run down for long passages, reducing weight and improving fuel economy. By adding watermakers to the NMEA 2000 system, the crew will know the water levels and how water-production capacity is faring.

Refit Considerations: Watermakers join the remote monitoring of NMEA 2000.

Sea Recovery, (800) 354-2000; www.searecovery.com

Pod Power

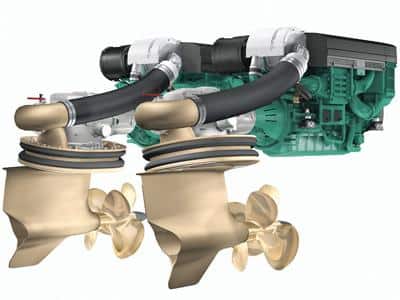

Azipod propulsion systems, such as Volvo Penta IPS and Cummins Mercruiser Zeus, have proven their value with performance, efficiency, and space savings in new builds. But what about for repower?

“When I came on for Volvo as an applications engineer and ever since I started working with IPS, I started thinking about repower,” says Tom Eckel, an applications engineer for Volvo Penta, who is repowering his own 1974 Bertram 38 as this article is being written. “Up until just recently it’s been Well we’re not really ready for that at this point. But now we’ve worked with so many boatbuilders, we know what works and what doesn’t work.”

Interested? “The first step is to qualify the boat,” says Eckel. “We need to take the measurements to make sure it’s going to fit under the cockpit sole without raising the deck. So obviously the lamination is a pretty serious part of the process. If you get into hull modifications on top of laminations, like raising your deck, it’s just not going to be cost-effective.”

Even if your boat has the room in the machinery spaces, the hull design may not work with the system. “When you start getting into 20-degree deadrise, you have to really start looking at your chines, to make sure that you have enough flat area so that when you go into a turn that you’re going to be stable,” says Eckel. “If you’ve got a soft chine and you’ve got a big deadrise, it’s not going to work because you’re going to have too much lean in the turns, it’s not going to be a safe, predictable turn. And we don’t like keels, because they tend to fight the tracking of the IPS drives.”

Eckel may know better than most what to expect for his Bertram project. “Just the rough numbers, my speed increase is probably going to be about 15 percent, the fuel is going to be anywhere from 30 to 45 percent, and the sound level is going to be half of what it was,” he says. “That’s just my gut feeling from what I’ve seen on other boats. There is no vibration with it, thanks to the contra-rotating propellers and the forward-facing props. Those rubber o-rings that keep the water out also isolate the drives.”

Refit Considerations: Less fuel burn and dime-radius turns? It’s worth exploring, though equipment costs are around $120,000.

Volvo Penta; www.volvopenta.com

Green Tee

Taking ownership of a yacht with a rich charter history, such as Mirabella III, is akin to buying an Old Master painting—you can do with it what you will, so long as you don’t screw it up for everyone else. Ownership of such boats is more than a legal concept. It’s a feeling in the hearts of charter clients who loved her, a week or two at a time.

And so it was that the British owner of Mirabella III, a 137-foot sloop built in Thailand in the 1994, had come to love her as well. Then the opportunity to buy her arose. “A spectacular boat in terms of its volume, it had has five guest cabins, huge, flush decks, an 11-story-high mast, just acres of room,” he said. “The opportunity to buy her came up a couple of years ago, and we have spent the last two years refitting, practically rebuilding her from the ground up.”

The owner felt a responsibility to the yacht, but he was also sensitive to the environment: “The most eco-friendly way of whizzing around the planet is sailing,” he says. “We stripped the engines down, and rebuilt them and we added in the fuel-processing equipment aboard. We burn fuel very economically and it produces far less toxic fumes…of the various grades of diesel that are used to power these boats, we will only use the most eco-friendly fuels. It’s easy to buy cheap fuel, but actually what you can get is black smoke out the back and it’s unpleasant and it’s not worth it anyway.”

Mirabella III had her appearance updated as well. “We even laid a new, flush teak deck,” says the owner. “We didn’t buy precut teak from a deck manufacturer, or a deck supplier. We sourced the raw teak itself from sustainable sources and had it shipped to Europe where it was cut and laid to our specifications…In effect it’s quite an economical thing to do.”

Even the entertainment on board has taken a greener turn. A new “beach” swim platform offers sun and swimming, but also lets golfers take swings at targets floated behind the boat. The difference: The golf balls on board are biodegradable and actually disintegrate into edible material. “They have their sport and feed a few fish,” says the owner. “What could be better than that?”

Refit Considerations: Green is becoming less the moral high ground and more the status quo. Look into green alternatives on any refit project—it may be less expensive than you’d expect.

Nicholson Yachts, (401) 849-0344; www.nicholsonyachts.com

Stop, Drop the Roll

Gyroscopic stabilizers are not new—the technology has been around since the early part of the last century. They were effective at arresting the undesirable movement of boats back then, too, but their size and power draw made them unwieldy.

“To make it more practical for recreational yachts…we had to develop a gyro that was lighter and demanded less power,” says Andrew Semprevivo, international sales manager of Seakeeper. “Spinning the flywheel in a near-vacuum let us spin a wheel faster while using less power.” In layman’s terms, a gyroscopic stabilizer with a lighter flywheel will give good performance if you can spin it faster.

The lack of air drag in the vacuum-packed unit means faster speeds, but with another key. “On our model 7000 gyro, we are spinning a 432-pound flywheel close to 10,000 rpm while drawing a max of 3 kW of power during spool-up and 1.5 to 2 kW while in operation,” says Semprevivo. “The operating power draw is similar to that of a hair dryer.” Today’s gyroscopes are already speeding toward the future. Seakeeper just rolled out its M21000 model, which can stabilize a 90-ton boat.

“We put an active control on the gyro to monitor the roll of the boat and the sea conditions” says Semprevivo. “It controls that precession rate so it matches a swell or a chop.” Precession means the gyro is working on the hull. “When the boat rolls port to starboard, the gyro precesses fore and aft, and exerts its torque,” he says.

Can you add this technology to your boat? “The most important thing when sizing gyros to a vessel is to have the proper amount of angular momentum for the vessel,” says Semprevivo. “Our gyros typically weigh one to two percent of the vessel’s displacement and reduce resonant roll by 60 to 80 percent.”

The installation may be much simpler than you’d think. “On planing boats we want it from midship aft,” says Semprevivo. “It does not matter where it is in relation to centerline. It will perform on centerline just as well as it will if it’s all the way to one side. And on multiple gyro applications, they’re totally independent, they do not rely on each other for anything and they can be installed in any manner.”

Refit Considerations: Take a look at reducing roll and adding to the enjoyment of being on board.

Seakeeper, (410) 326-1590; www.seakeeper.com

Filter Tips

It’s true that those fuel Racor fuel filters in your engineroom look just like the ones your father had on his boat when you were young. The turbine model was introduced in the late 1960s and, as they say, if it ain’t broke… So very little has changed—on the outside. But the element of that filter has been evolving and adapting right along.

“We’ve improved the soul of the filter which is the media, or the element that goes inside it,” says Robin MacDonald, marketing and sales manager for Village Marine Tec., an operation of Racor Division. “The media that’s pleated in the paper, if you will, is not really paper, it’s a cellulose mixed with engineered fibers and it’s always evolving to match current requirements of engine builders. Particularly since most diesel engines are using common-rail fuel injection, the pressures have gone up in the fuel system. This means tolerances in the pumping components and the injectors are tighter, which means a need for higher fuel filtration efficiency and capacity.” Evolving filters remove smaller and smaller particles and water traces.

Biofuels also present certain challenges for fuel filters. “Because water doesn’t want to fall out of biodiesel as easily as it does in diesel,” says MacDonald. “The challenge is water removal. As a rule of thumb, anybody can upgrade their engine fuel system [to biodiesel] by adding and doubling the size of the prefilter/water separator. Slow down the flow of fuel across the media, and it allows facilitates the removal of free and emulsified water.”

**

Refit Considerations:** Better filtration means more efficient engines with less downtime, and the possibility of biofuel options.

**Racor Division, Parker Hannafin Corpation, (209) 521-7860; www.parker.com/racor

**