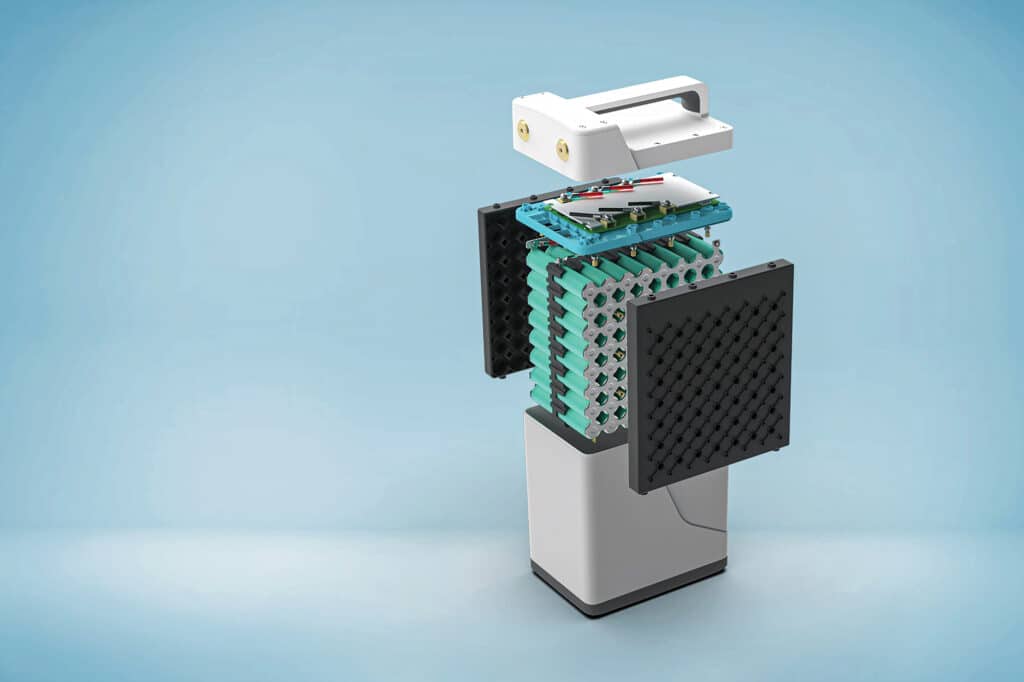

Aceleron’s essential batteries are the world’s first modular high-performance batteries. The company designed the lithium-iron-phosphate batteries for the circular economy, so all componentry is modular and can be removed. Aceleron enables this via its clever use of compression—screws, fasteners, bolts and trays that mechanically sandwich individual lithium cells together to form battery packs—rather than the traditional methods of gluing or spot-welding componentry. This lets owners replace components while facilitating future upgrades. “As better cell technology becomes available, existing cells and components can be removed for repurposing, and the newer, more-efficient cells can be installed,” says Carlton Cummins, Aceleron’s co-founder and chief technical officer.

Given the importance of high-performance batteries and their safety considerations, Aceleron had to thoroughly vet the tech. “We had to ensure our new assembly technology could perform just as well as incumbent technology for assembling batteries,” Cummins says. The time investment paid off, and Essential batteries are now internationally certified and compliant with National Marine Electronics Association standards.

Each Essential battery has a modular battery-monitoring system, Bluetooth connectivity and two CAN bus connection ports. This allows users to monitor their batteries’ health and performance metrics locally via an onboard network.

Power Up

Aceleron’s Essential batteries are available in 12, 24 and 48 volts; each is rated to 5,000 charge/discharge cycles. The batteries can be installed in three orientations. As space allows, they can be run in parallel to theoretically supply unlimited amounts of electricity. The company sees uses on boats as well as in other applications, including on motor homes, with all-terrain vehicles and in telecommunications stations. The lightweight design also makes the batteries usable in mobile applications.