Horizon Yachts has delivered more than 910 yachts worldwide in 36 years. It is one of the 10 largest yacht builders in the world. The company has four specialized shipyards and employs 800 people—and, in the past four years, has taken dramatic steps to “rebuild.”

Horizon’s CEO, John Lu, added seven new bays for fitting out hulls, allowing for approximately 15 yachts to be under construction at any given time. This system eliminates the need to move hulls from one shed to another, saving time. Other upgrades include a 3D printer, a precision five-axis router and a cafeteria. A 1,000-ton ship lift is in the works too.

Investing upward of $30 million on all these changes during the pandemic may have seemed risky, but Lu was simply going ahead with previously laid plans.

“The first six months, everything stopped,” he says. “Six months after, everything was booming.”

As a result, Horizon emerged from the pandemic as an even more viable force in the yachting marketplace. Its subsidiary Atech Composites produces all of the hulls, decks and superstructures for every Horizon yacht. Founded in 2000, Atech is Asia’s premier builder of large-scale fiber-reinforced plastic, with other customers in aviation, transportation and wind-farm components. It built pieces of the Great Harbor Bridge, the first horizontally rotating landscape bridge in Taiwan.

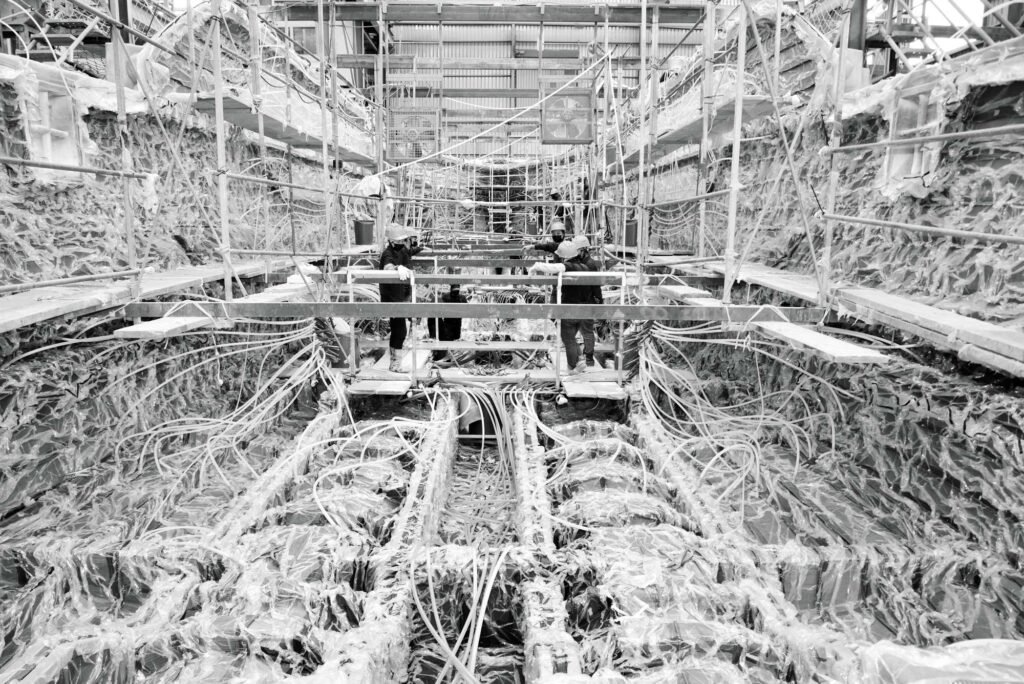

For Horizon, Atech is responsible for a number of advancements in yacht construction. One of them is called 6D resin-infusion technology. In the past, resin infusion was a 3D process that let the resin flow up and down internal stiffeners, creating large fiberglass hulls. The 6D process adds 3D structural fiber cloth to the 3D resin process, guaranteeing even resin distribution around corners, over integrated stringers and throughout the laminate. The end result is lighter, stronger hulls that Horizon can now build in any length in a single shot. Atech’s largest hull to date with this process is a 140-footer with girders and framing.

Prior to any infusion, the component plug has to be laid out with fiberglass sheets, cut to size, and oriented by the glass direction. This is a manual yet methodical process performed by craftsmen, who demonstrated their skills during my visit, setting up stations to show the types of fiber weaves, the flow of resin through the various weaves (thicker cloths took longer), and the ability to use the proper fiber in the right areas. One interesting assurance measure Atech performs is 3D profile measuring, or reality capture. This process creates a 3D model from laser scans, then compares the finished product’s scan to the blueprints to ensure proper profile dimensions.

Other Atech developments include low-shrinkage resin solutions such as Hyver, which results in smoother surfaces; the orientation and type of fiber fabrics for strength in high-load areas; and infrared thermography to measure temperature differences. With environmental stewardship in mind, Atech says, the resin-infusion process reduces volatile organic compounds emissions by almost 80 percent.

Once a Horizon Yachts hull is created, most of the components are sourced internally. During my time at the shipyard, I viewed many yachts in production, as well as an array of new models in the water and the Horizon City Marina. This year, Horizon Yachts introduced the FD90, two FD80 models and the V77 cockpit motoryacht, which is tricked out for fishing.

Horizon’s team hinted that there might even be a 130-plus-footer in the future. And the builder has partnered with Lexus to build the next iteration of its yacht, the LY680.

Setting Standards

The Atech Composites lab’s responsibilities include quality assurance and advanced technology development. Incoming raw materials are tested to ensure proper specifications. Random testing throughout the construction line is performed as well. Advanced development teams test for mechanical resin flow, weather resistance, fire retardant, discoloration and more.

Tools of the Trade

Horizon’s Atech lab uses viscosity meters and thermostatic baths to ensure proper construction. Moisture meters, Barcol hardness testers (which measure the hardness of components) and color spectrum meters are utilized too. Tensile testing checks the breaking point of key components.

Detect and Repair

As part of the inspection process, nondestructive testing is performed on every critical area to identify defects by analyzing strain under loads. Utilizing laser lights and CCD cameras as part of the shearography system, the builder looks for disbanding, dry spots, voids and other defects.

Take the next step: horizonyachtusa.com